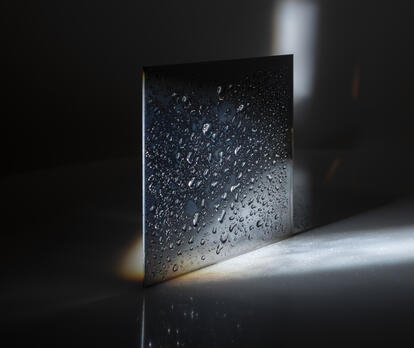

Hydrophilic/hydrophobic coatings

on glass and metal change their wetting properties: either with a hydrophobic effect by increasing the contact angle (lotus leaf effect) or with a hydrophilic effect with the formation of a closed film achieved by reducing the contact angle.

An anti-fog coating is often used in combination with other coatings (e.g. anti-reflection coating).

With hydrophobic coating ("lotus effect"), the water forms large drops and then drains off.

With hydrophilic coating, a continuous film of water forms that does not hinder transmission - important at horizontal surfaces

Material types and sizes

We offer the following materials with anti-fog surface coatings:

We coat not only different types of glass but also different metal surfaces – in each case according to the customer’s specific application requirements.

You can find all technical data here:

Glass - standard thicknesses

| Float glass | 2 mm | 3 mm | 4 mm | 5 mm | 6 mm |

| Borofloat glass | 1.1 mm | 2 mm | 3.3 mm | 5.5 mm | 6.5 mm |

| Clear glass | 2 mm | 3 mm | 4 mm | 5 mm | 6 mm |

Thicknesses of metal or plastics

according to specification / customer request

Standard sizes

| minimum | in mm range depending on material |

| maximum | gross 1,150 x 850 mm / net 1,080 x 800 mm |